FAQ

- Why use Closed Cooling?

- What is a Full System?

- What is a Half System?

- Preparing for a New Season (Spring Outfitting)

- Off-Season Storage ( WINTERIZING )

- Should I add freshwater cooling to an old engine?

- What’s wrong with raw water?

- I keep the engine flushed.

- What extra maintenance is required if I add freshwater cooling to one previously operated on raw water?

1. Why use Closed Cooling?

A fresh, treated water cooling system is well recognized as an effective way to preserve your engine. By routing raw water, with its included salt, mud, marine organisms and debris into the corrosion resistant, long lasting heat exchanger system instead of the coolant passages in your engine block, there are fewer places for accumulation of deposits, and the raw water is never exposed to the high temperatures of the block—which can lead to undesirable deposition. The block is in contact with treated fresh water only, normally including anti-freeze and rust inhibitors, which preserve and protect your valuable engine. A closed cooling system provides a foundation for installing cabin and water heating systems using heat from your engine. We make kits for either FULL Systems or HALF Systems. Click on the navigation buttons for an explanation of the difference. Our heat exchanger kits can be easily installed, even while your boat is in the water. A boat fitted with a fresh water cooling system will hold its resale value far better than one which is direct cooled with raw water. You can enjoy your boating experience more knowing that your engine is protected with a quality ORCA Marine Cooling System.

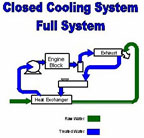

2. What is a Full System?

In a FULL system (i.e. engine block and exhaust manifolds) all parts of the engine are cooled with circulated treated fresh water. Raw water which has removed heat from the engine through the heat exchanger is then injected into the exhaust elbow to quench the exhaust.

This system provides the maximum protection to your engine from the ill effects of direct raw water cooling.

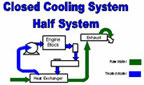

3. What is a Half System

In a Half System (Block Only) closed cooling system, the treated fresh water is circulated through the engine block, thermostat, expansion tank, heat exchanger and circulation pump. It is not routed through the exhaust manifold(s). Raw water which has removed heat from the engine through the heat exchanger is then injected into the exhaust manifold, from which it flows to the exhaust elbow to quench the exhaust.

This system does not provide the same degree of protection for your engine as a FULL (Block and Manifold) closed cooling system, but is generally easier to install, less expensive, and may be the only option available if your engine’s pump capacity, electronic control system, or other factors prevent a FULL system from being safely installed on a particular engine or boat.

4. Preparing for a New Season (Spring Outfitting)

Spring is an exciting time, when boat owners begin to think seriously about getting their boats back in regular use again. One way to help insure that your upcoming season will be enjoyable and trouble-free is to make a thorough check of your engine cooling system before taking off on that first trip.

If your boat was properly winterized (as it surely was) then there will be no concern about freezing damage. If for any reason there is some possibility of freezing damage, the system should be pressure tested on both the raw water and the fresh water loops to insure that there are no leaks in the system.

Check the coolant (antifreeze). Since you topped this off as part of winterization, it should still be full. If there has been a loss of fluid, it means that there is probably a leak in the system somewhere, and it would be a good idea to locate it. If you did not winterize, then your system may need to have the coolant level topped up and checked for specific gravity with a hydrometer. If the specific gravity is off-spec (about 1.075 at 60F) or if the coolant has been in the system for two or more years, then it should be replaced. As the fluid ages it loses the chemicals that inhibit corrosion and lubricate the pump. If you replace with an extended-life coolant product you can extend the replacement intervals to 3 to 5 years.

Inspect all hoses and fittings, in both the raw water and coolant loops. Hoses should be flexible and free of cracks; fittings should have no tell-tale streaks indicating leaks.

Check your alarm circuits. This can be done by simply grounding the appropriate connection on the alarm switch. While this does not test the functioning of the switch (so you should not get overconfident about your system) it will test the rest of the system for continuity and function of the audible alarm.

If not done during winterization, check the heat exchanger. Remove the end caps to drain and inspect the heat exchanger. Clean out any debris. Make sure you inspect the end caps for contour and cracks and replace the neoprene gaskets before putting the boat back in service. Inspect the zinc anode often during use and replace when half gone. If you find rubber bits in the exchanger, they probably came from the raw water pump. Check the pump (see next paragraph below). The sacrificial zinc anodes frequently spall, and there will probably be zinc bits in the exchanger which should be cleaned out. We now produce a “Tune-Up” kit with replacement gaskets, end caps, zinc and mounting bolt plus a soft clean-out rod to make it easy to keep these parts in good working order. Note that if you use a clean-out rod, it should be softer than the copper tubes, and should not be used to dislodge materials which are firmly stuck to the tube surface, as this could damage the tubes. The rod will assist in cleaning our bits of grass, zinc, shells, and similar materials which are just lodged in the tubes or on the face of a tubesheet.

Unless already done during winterization, check the raw water (sea water) pump. Replace the impeller if it is worn or over two years old. You have to remove the impeller to inspect it, and many boaters skip the inspection part and just replace the impeller every year as a routine – since you have to do all of the work just to inspect it. Be sure there are no impeller parts lodged in the hoses or elsewhere in the system as they will eventually move to an inconvenient place and restrict water flow. The raw water pump impeller should be replaced every two years or whenever it is found to be worn or have damaged blades. Be sure to re-assemble with the proper gaskets and grease.

Check the raw water (sea water) strainer. Clean and inspect the trash basket in the strainer to insure that it fits properly and water will flow freely. You might as well service the seacock while you are in the bilge and exercising the valve anyway.

Check the engine oil and transmission oil reservoirs for water (as well as proper level). Any water in the oil is a sign of a leak in its respective heat exchanger, and you will want to eliminate the leak and replace the oil before the engine is run. Unless you are really good with engines you may want to have the engine professionally checked if you found water in the oil, as a little water here can do a lot of damage in a short time.

Run the engine. Inspect a wet exhaust for water discharge through the exhaust ports, and look for fitting and end cap leaks while the engine is running. After shutting down and giving the engine a few minutes to hot soak check again for leaks.

Enjoy the boating season.

5. Off-Season Storage ( WINTERIZING )

Winterizing a fresh water cooling system.

Water expands as it freezes, and will deform or break metal parts if it is constrained. Because of the way ice forms it can break parts even if the part is only partly full of water. The primary winterization task is to insure that there is no water which may freeze in parts which do not permit sufficient expansion. This generally means that all raw water should be removed from the system, whether introduced by running in fresh water, or flushing the raw water circuit.

Replace the antifreeze based on the engine manufacturer’s instructions, ensuring it is the correct mixture for complete protection in your climate. If your antifreeze mixture is two years old you should replace it. As the fluid ages it loses the chemicals that inhibit corrosion and lubricate the pump. If you replace with an extended-life coolant product you can extend the replacement intervals to 3 to 5 years.

Full system (100 %) – Antifreeze protects the engine block and the exhaust manifold(s). You must drain any standing raw water from the rest of the system.

Half system (50 %) – Antifreeze protects the engine block only. You must drain any standing raw water from the rest of the system.

Drain raw water from any incoming raw water filter, any heater if separate from the antifreeze circuit, any water pump, any oil, gear, transmission or power-steering coolers.

Remove the raw water supply hose at the lowest point which most easily drains the above accessories.

Remove the end caps to drain and inspect the heat exchanger. Clean out any debris. Make sure you replace the neoprene gaskets before putting the boat back in service. Inspect the zinc anode often during use and replace when half gone. If you find rubber bits in the exchanger, they probably came from the raw water pump. Check the pump and replace the impeller if it is worn or over two years old. Be sure there are no impeller parts lodged in the hoses or elsewhere in the system as they will eventually move to an inconvenient place and restrict water flow. The sacrificial zinc anodes frequently spall, and there will probably be zinc bits in the exchanger which should be cleaned out.

All cooling systems depend upon a steady and reliable flow of water. Inspect and maintain your raw water strainer and pump according to your owner’s manual. When you check the strainer be sure there is a basket or screen securely in place.

6. Should I add freshwater cooling to an old engine?

First, let’s be clear: the best time to install freshwater cooling is when the engine is brand new. Only then will there be no adverse effects from operating with raw water cooling.

However, if you have an engine with some time on it in raw water cooled mode, adding fresh water cooling will either arrest or slow further deterioration – which is better for the engine than continued operation with raw water cooling. Adding a freshwater cooling system will not repair the damage already existing from operation with raw water, and will require some additional maintenance as your engine flushes out rust and scale which have built up on the internal cooling passages. Ultimately, whether the extension of life of your engine is worth the cost of the freshwater cooling system will depend on the condition of the engine.

7. What’s wrong with raw water?

If you plan a short life for your engine and you don’t care about operating efficiency – there is nothing wrong with raw water cooling. A lot of boats operate that way. Following are some of the problems created with raw water cooling:

- All raw water is oxygen rich (that’s why fish and other marine life survive in it). A steady bath of hot, oxygen rich water on cast iron is a sure path to severe rust. Add salt and it’s a lot worse. The rust forms by oxidation of the engine block and exhaust manifolds from the inside (so you can’t see it). This rust is flushed out with the water going to the exhaust, constantly exposing fresh metal for further rusting. Eventually these parts will fail, usually at a gasket surface or elbow.

- All raw water contains impurities. Even if you only run your boat in fresh water lakes, that water contains biologic organisms and probably suspended solids (mud, sand and sediment). If the engine ever operates in shallow water (like at a boat ramp) it will pick up even more sediment. This material tends to stick to the hot metal of the block and manifold, and will not be fully removed with further operation or vigorous flushing (although these help). Dissolved solids, like salt, will also deposit on the hot walls. These deposits insulate the engine from the cooling water, reducing the effectiveness of the cooling water, create hot spots in the engine and restrict the flow of cooling water.

- Raw water cooled engines run cold. In order to reduce the deposition problem (see #2 above) raw water cooled engines are generally fitted with a lower temperature thermostat than the engine was designed for. This reduces engine efficiency, which decreases with decreasing temperature (the hotter the better, within its design limits).

8. I keep the engine flushed.

Flushing is good, but will just reduce the problems associated with raw water, not eliminate them. Hard deposits will not be fully dislodged by flushing, even when salt dissolving treatments are added to the flushing water. At least one source has reported that most flushing systems are inadequate to insure full cooling during the flushing cycle, because a garden hose (about 5 gpm max) just can’t supply as much water as the engine is designed to receive (frequently 10 to 20 gpm or more). This can leave coolant passages located high in the engine and far from the water pump dry – thoroughly cementing any deposits located there. When you flush, be sure you have a water source that matches the engine requirement.

9. What extra maintenance is required if I add freshwater cooling to one previously operated on raw water?

Rust, scale and any loose deposits in your engine coolant passages are continually flushed out of the system through the exhaust when operated on raw water. When a freshwater system (also called a closed cooling system) is installed, there is nowhere for these materials to go, so they will circulate until they find a quiet corner somewhere to stop. Usually that will be in the heat exchanger, on the shell side, which is difficult to clean. If the rust, scale or deposits are abrasive, they will (in effect) be sandblasting your cooling system as they circulate – cleaning out the system (and possibly causing erosion of cooling system parts) but adding to the load of debris that is circulating. This stuff must be removed, which requires several cycles of draining and flushing of the coolant (antifreeze) side of the system (including the heat exchanger) until it is clean. Used antifreeze solutions are considered toxic and require proper disposal.